Recent change in OSHA Standards for Fall Protection

- share

What You Need to Know About OSHA and Your Fall Protection.

Many people find it challenging to keep abreast of current OSHA standards. They are designed to be comprehensive, and the legally wording can be tedious to wade through at times. However, the important thing to remember is that they are in place for your safety and protection.

OSHA recently announced a change to the LABOR 2910 CFR Part 1910 Walking-Working Surfaces and Personal Protection Equipment requirement. This change applies to high lift trucks designed to lift personnel such as the Orderpicker or Swing Reach trucks. These models now require a Fall Protection System consisting of either a restraining means such as guard rail system or means for securing personnel with a harness and either an energy absorber or self-retracting lanyard. No longer will a body belt be considered an appropriate part of a fall protection system. This new standard went into effect on January 17, 2017.

Fall Protection is an area that is particularly important. If your operation requires employees to work on elevated equipment, such as aerial work platforms or order pickers, you need to know that the appropriate fall protection will keep you from serious injury or death. A proper check of your fall protection can mean the difference between a minor incident or a heartbreaking incident.

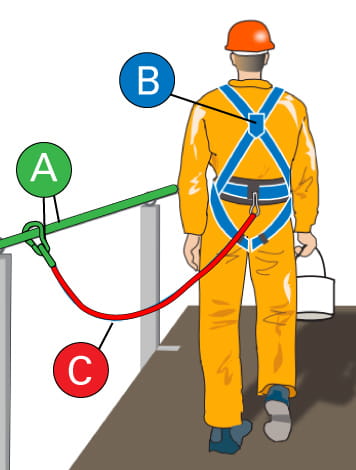

So, how do you know if your fall protection is right for your operation and ready to use? Let's take a look at the basic components of a fall protection system. OSHA recommends using the “ABC” system when inspecting fall protection:

- A - Anchorage / Anchorage Connector. This is the anchor point you attach to. Aerial work platforms are required to have engineered, approved anchor points. Order pickers typically have an overhead anchor.

OSHA requires an anchor point to be capable of holding 5000lbs per worker, or twice the expected impact load of a worker falling 6 feet. When inspecting your anchor prior to use, look for damage such as bends, wear on the attachments, and rust or cracks at welds.

- B- Body Wear. This body harness must have proof of certification attached. It must be made of synthetic material and in good condition. Inspect it thoroughly for cuts, abrasions, pulled stitching, or signs of chemical damage or decay.

Remember that you should never use paint, markers, or any other chemicals on the harness. If identification is needed, use a name tag attached in a way that does not compromise the integrity of the webbing.

- C- Connecting Device. This includes lanyards or deceleration devices, snap hooks, etc. Check lanyards in the same way as a body harness. Any sign of deterioration at all means it is not useable. A lanyard that has been subjected to a shock load or fall must be taken out of service immediately."

They must be capable of stopping a fall completely within 6 feet. Self-retracting lanyards must be capable of holding 3000lbs, and allowing a fall of no more than 2 feet. Any lanyards allowing falls of more than 2 feet must sustain a load of 5000 lbs. During inspection, pay special attention to the stitching on lanyards, as they are designed to decelerate a fall by allowing a controlled tearing of the stitching.

The most important part of inspection is making sure that it is installed and used correctly. A perfect lanyard is useless if it's attached to a faulty anchor, and a solid anchor will not save you if the harness is not buckled securely. Here are some points to consider:

- Get trained - Proper training is not just a legal requirement, it's a lifesaver.

- Form follows function - The “cool” operator that “doesn't need Fall Protection” is asking for a fine, expulsion from many worksites, and possibly a death sentence in case of an incident.

- Wear it right - This means the harness is the right size for your frame, fits snugly (no slack), and has all straps routed properly and securely. When in doubt, check the operator manual that comes with the harness.

One last thing to consider is those around you: if you see others working in an unsafe manner, talk to them or their supervisor. Remind them that their families and employers need them to go home safe. Your reminder may just save a life, and it helps build a culture of safety.

If you have any questions or need to explore material handling options and training for your worksite, contact your account representative today.

Safety Training | Warehouse Products